Ream Paper Cutting Packaging Machine Automatic A4 PA

Basic Info

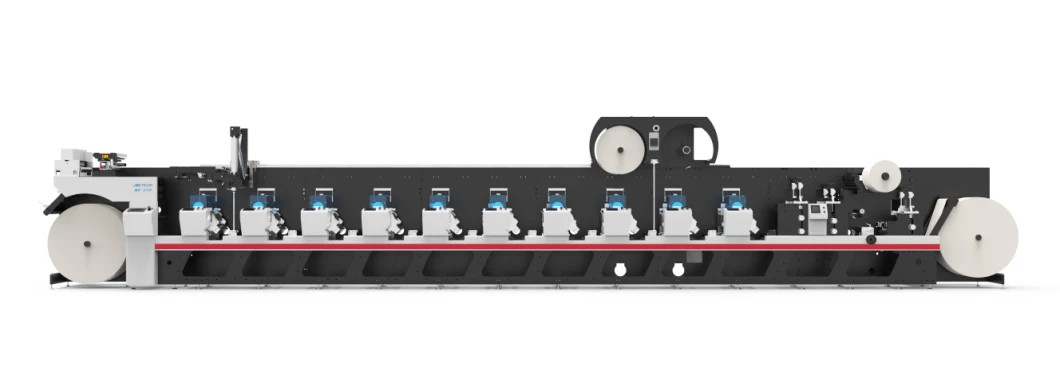

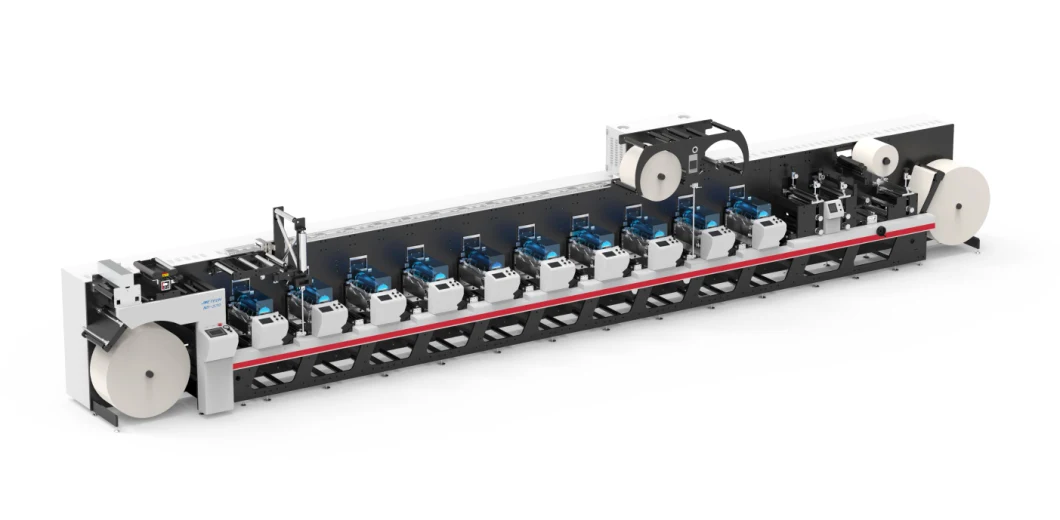

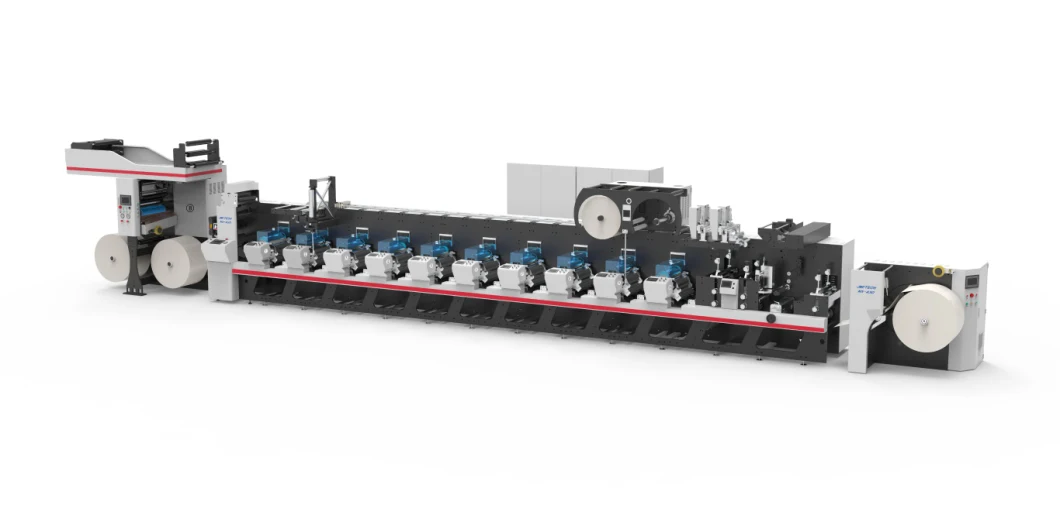

| Model NO. | N5 |

| After-sales Service | Service for Whole Life |

| Warranty | 12months |

| Printing Page | Single Faced |

| Printing Color | up to 20 Colors |

| Anilox Roller | Ceramic Anilox Roller |

| Dryer | LED, UV, Hotair/IR |

| Type | Flexo Inks |

| Embossing Structure | Flower Head, Flexo |

| Structure | Inline |

| Application | All Kinds of Labels |

| Automatic Grade | Automation or Manual |

| Printing Speed | 200m/min |

| Substrate Width | 1270 mm |

| Min. Width | 340 mm |

| Machine Speed | 180 M/Min |

| Gear Pitch | Z = 3.175 mm (Helical 1/8") |

| Waste Matrix Rewinder Diam | 700 mm (27.5") |

| Transport Package | Wooden Case |

| Specification | from 2color to 20 colors |

| Trademark | Jmetech or Gidue |

| Origin | Xi′an |

| HS Code | 844316002 |

| Production Capacity | 40 |

Product Description

1270 Packaging Paper Cutting MachineThis series of equipment is innovatively developed by our company based on years of production experience in paper cutting machines and single sheet automatic collection systems, and has applied for a national patent. Mainly used in the production of printing and packaging products in the fast food industry, including the production of hamburger coated packaging paper, hamburger boxes, potato chip boxes, meal tray paper, paper cups, etc.This equipment adopts an innovative process to replace the traditional multi process process technology (rolling narrow products into rolls for wind cutting and forming inner product packaging) with wide roll to roll, offline strip overlapping, and high-speed cutting and forming. This can reduce paper waste by about 3-5%, save a lot of human resources and multi process losses, greatly improve production efficiency, shorten delivery time, and greatly reduce direct contact with this packaging during the production process.The C-type machine is a new type of cutting machine that is upgraded from the original single frame offline paper wrapping cutting machine. It can use double frame feeding (printed products) and complete strip cutting work through double layer positioning. The efficiency is twice that of a single frame machine, which can achieve double layer positioning cutting and greatly improve production efficiency.

Substrate: PS label(Paper, PET, BOPP, PVC), light carton upto 350gsm, mono film PET from 15um,PVC, BOPP, PE, PA from 20um, laminate tub PBL and ABL.

has a professional design team engaged in the printing industry for more than 20 years, there is a production team that has created miracles in the industry, the company is now focusing on the research and development, production and sales of flexo printing machines, digital printing machines, special models and OEM various specifications of high-quality digital platforms (including POD, books, flexible packaging, corrugated boxes etc.), the company takes the core technology as the traction, catches up with the international well-known brand in machine performance, and wholeheartedly provides users with high quality, efficiency, stability, Cost-effective equipment and service. The company has good cooperation with Shenzhen Xianjunlong, Fujian Nanwang Group, Ningbo Chengyi, Agfa Group, Beijing Shengde, Shenzhen Runtianzhi etc. and has more than 20 patented technologies, filling a large number of domestic and foreign gaps. The company is headquartered in Xi'an, in Guangzhou, Xi'an, Shanghai has a professional sales team and after-sales service team to provide users with professional and efficient solutions.

Q: Your factory is trading company or factory? A: We are factory. We have more 5000 square meter workshop and 80 workers ,We accept customized services, research and design. We are Factory, so we have cost advantage than others Q: How do your company control the machine quality? A: First we control the raw materials quality. Second, we control the quality of machine when we are processing. Third, Our installment engineer will test machine.

Q: How about payment term, payment safety and delivery time? A: We accept 30% deposit, balance before shipment. And Irrevocable L/C at sight. Delivery time is 20 to 30 days. It is according to order quantity. Q: What is your company after sale service? A: Our installment engineers are available. Normally it will take about 7 to 10 days for all.

Our guarantee is one year. If there is any spare parts is broken, we can send them freely to you.